Protected areas

01 / Storage rooms

Protected area

Storage rooms are used for the orderly storage of materials, products and operating supplies. Depending on their purpose, they may contain office and consumable items, cleaning and hygiene products, tools, spare parts or merchandise. In some cases, refrigerated or deep-freeze units are integrated, which place additional demands on ventilation, temperature control and fire protection.

The wide variety of stored goods and packaging materials results in differing fire loads and requires a coordinated protection concept.

Risks

- Short circuits in electrical wiring or distribution cabinets

- Carelessly discarded cigarettes or other ignition sources

- High fire load due to densely stored materials and packaging

- Rapid fire spread in the absence of fire compartmentation

- Overheating of equipment or lighting systems

Solution

In storage and logistics areas, sprinkler or water spray systems are primarily used. They ensure area-wide cooling and rapid fire suppression, with sprinklers also being integrated directly into rack systems depending on the storage type. Cold storage rooms are safely incorporated into the extinguishing concept using dry sprinklers to prevent the pipe network from freezing.

In enclosed storage rooms or areas with particularly high-value goods, AccurateFlow provides an effective additional layer of protection. By using inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is reduced and combustion is reliably suppressed — residue-free, gentle on materials and low-maintenance.

02 / Paint and varnish storage areas

Protected area

Paint and varnish storage areas are among the most sensitive hazardous materials zones, as flammable liquids, thinners and solvents are stored there. Due to the high fire and explosion risk, these rooms are subject to strict legal requirements. These include spill containment trays, firefighting water retention, explosion-proof lighting and ventilated shelving systems. Paint mixing rooms with pumping or dosing equipment are often integrated, introducing additional fire loads and ignition sources.

Risks

- Technical defects in pumps, mixing or dosing equipment

- Overheating of electrical components and lighting

- High fire load due to stored paints, thinners and solvents

- Ignition of vapours caused by insufficient ventilation

Solution

For paint and varnish storage areas, sprinkler systems with foam concentrate proportioning are particularly suitable. They provide area-wide fire suppression and effectively prevent the spread of flammable liquids. The foam forms an airtight blanket on the surface, suppresses vapours and prevents re-ignition.

In enclosed or highly sensitive storage rooms, AccurateFlow offers an ideal complement. The inert gas technology (IG-100, IG-01, IG-55, IG-541) extinguishes fires without residues and avoids chemical reactions with the stored substances — clean, gentle on materials and low-maintenance.

Fire detection is provided by flame and heat detectors, which are connected to a central fire detection system to ensure rapid and precise activation of the extinguishing systems.

03 / Filter systems

Protected area

Filter systems are used in nearly all industrial production processes in which dust, particles or vapours are generated. They clean the process air, protect downstream equipment and contribute significantly to operational safety. Particularly fine and combustible dusts are produced during milling, grinding, cutting or polishing of wood, plastics, metals or composite materials. Through interconnected piping, the filter units are closely integrated with extraction and conveying systems — making them a central, yet fire-prone, component of the overall installation.

Risks

- Formation of explosive atmospheres due to dust-laden air

- Ignitable deposits in filter bags or cyclone separators

- Introduction of embers through extraction ductwork

- Rapid fire spread within the filter housing or collection hopper

- Secondary explosions caused by dispersed fine dusts

Solution

Filter systems require an exceptionally fast and residue-free extinguishing method that protects sensitive filter media and minimises the risk of explosion. AccurateFlow provides a highly effective solution: by introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is reduced below the ignition threshold. Fires are smothered within seconds, and re-ignition is reliably prevented.

For open or large-volume filter units, a finely atomised water mist system can be used as an additional measure to effectively reduce heat and smoke.

Activation is automatic via the fire detection system, using temperature, flame or smoke detection to ensure a precise and rapid response in an emergency.

04 / Production and Assembly Halls

Protected area

Production and assembly halls provide large areas for machinery, manufacturing lines and conveyor systems. They are often designed as open spaces in which production, storage and transport zones interconnect seamlessly. Automated systems and high power densities require a stable energy supply while simultaneously creating increased fire risks. Open building layouts without defined fire compartments promote rapid fire spread across wide areas.

Risks

- Electrical faults in machinery, control systems or power distribution

- Combustible production and packaging materials

- Rapid fire spread due to open hall structures

- Overheating of heavily loaded system components

Solution

For large production and assembly areas, automatic sprinkler systems provide the most reliable protection. The principle of selective extinguishing enables targeted fire suppression only in the affected zone — leaving the rest of the production environment largely unaffected.

Depending on the process environment and material characteristics, finely atomised water mist systems or foam extinguishing systems can be used to reduce water consumption, protect sensitive equipment and prevent secondary damage.

Activation is carried out via a fire detection system with smoke, heat or multi-sensor detection, ensuring a rapid and precise response.

By combining area-wide water-based protection with intelligent control functions, a high level of operational safety and production continuity is ensured.

05 / Hazardous materials and flammable liquids storage areas

Protected area

Hazardous materials and flammable liquids storage areas (in accordance with the Flammable Liquids Regulation) are designed for the safe storage of substances that are highly flammable, explosive, harmful to health or hazardous to the environment. They may be constructed as separate buildings, enclosed rooms or integrated into existing production facilities.

The design of these storage areas is subject to strict legal requirements — including spill containment trays, firefighting water retention, explosion-proof equipment and the avoidance of potential ignition sources. The objective is comprehensive protection of people, the environment and infrastructure while ensuring a high level of operational safety.

Risks

- Rapid fire spread caused by highly flammable liquids and vapours

- Chemical reactions between burning materials and extinguishing agents

- Release of hazardous substances posing risks to personnel and the environment

- Explosions or pressure build-up in closed containers

- Extreme heat development in liquid and chemical fires

Solution

Fire protection in hazardous materials storage areas depends on the type and quantity of the substances being stored.

AccurateFlow provides an especially suitable solution: inert gas technology (IG-100, IG-01, IG-55, IG-541) reduces the oxygen concentration in a targeted manner and suppresses fires without leaving residues and without causing chemical reactions with the stored media.

Activation is carried out via a fire detection system with flame or heat detection, ensuring rapid and precise system activation.

For high fire loads or larger volumes, water mist or foam extinguishing systems can be used in addition, providing effective cooling and vapour suppression.

If extinguishing water does not pose a risk to the stored goods, high-pressure systems (e.g. Marioff) or low-pressure sprinkler systems (VID Firekill, Econaqua) can also be integrated.

06 / Parking areas

Protected area

Parking areas and underground car parks are integral components of modern building structures. They provide parking spaces for employees, customers and visitors, and are often designed as multi-storey or underground facilities. Due to the high vehicle density, limited air circulation and intensive use, they place special demands on ventilation, smoke extraction and fire protection. In addition to ensuring personal safety, the primary focus is on containing vehicle fires and preventing the spread of smoke.

Risks

- Technical faults in vehicles (e.g. short circuits, battery or fuel fires)

- Careless smoking or open flames

- Arson or intentional ignition sources

- Rapid fire and smoke development due to confined structural layout

- Heat accumulation and insufficient smoke extraction in lower levels

Solution

In parking structures and underground car parks, water-based extinguishing systems are primarily used to quickly suppress fires and prevent them from spreading to adjacent vehicles. Water mist systems from Marioff or VID Firekill nozzles provide a particularly efficient and resource-conserving solution, as they achieve strong cooling performance with minimal water consumption and reduce consequential damage.

For large ceiling heights or expansive parking decks, automatic sprinkler systems are used. They are supplied via the existing firefighting water network and ensure uniform area coverage.

A fire detection system with smoke or heat sensing ensures early alarm activation — providing maximum protection for people and property in highly frequented parking areas.

07 / Mechanical conveyor systems

Protected area

Mechanical conveyor systems are an essential component of many industrial production processes. They transport raw materials, auxiliary materials and operating supplies between individual processing stations via belt, roller or chain conveyors. These systems may be designed as open or enclosed units and often extend across multiple levels and building sections. Due to continuous movement, friction and their proximity to other production equipment, they present an increased fire risk that requires a fast and targeted extinguishing response.

Risks

- Overheating of roller bearings, drives or shafts

- Sparking caused by maintenance or welding work

- Self-ignition of conveyed materials due to friction or material build-up

- Fire spread along conveyor routes

- Difficult fire suppression due to enclosed constructions or continuous material flow

Solution

For conveyor systems, water spray extinguishing systems are used, providing an immediate and area-wide response along the entire conveyor route. They effectively suppress open flames and prevent fire spread to adjacent system components.

In sensitive production environments or where low water consumption is required, finely atomised water mist systems are deployed. They rapidly reduce temperatures, bind smoke particles and minimise consequential damage.

Fire detection is carried out via a fire detection system with flame or multi-sensor gas detectors, which precisely register changes in temperature and smoke.

08 / Delivery zones

Protected area

Delivery zones are used for receiving and temporarily storing raw materials, auxiliary materials and operating supplies, making them a central component of internal material flow. Depending on the facility design, deliveries take place either outdoors or within covered hall areas — often with both variants operating in parallel. High vehicle frequency, intensive forklift traffic and temporarily stored materials are characteristic features of these zones. These factors create an increased fire risk that requires a reliable and adaptable protection concept.

Risks

- Self-ignition of delivered or stored materials

- Formation of explosive atmospheres due to dust or vapours

- Arson or carelessly discarded cigarette remnants in outdoor areas

- Technical faults in trucks, loading equipment or conveyor systems

- Rapid fire spread caused by open structures and air movement

Solution

In open loading zones and outdoor areas, infrared or thermal imaging systems are used for early detection of temperature increases. If a hot spot is detected, an automatic alarm is sent to the fire detection control panel.

For targeted fire suppression, stationary or remotely operated monitors are deployed. They apply water- or foam-based extinguishing agents precisely to the fire source while simultaneously cooling adjacent structures.

In covered hall areas, sprinkler or water spray systems provide area-wide fire suppression — even in environments with large ceiling heights or increased dust levels.

Activation is automatic via a fire detection system with smoke, flame or heat detection, adapted to the respective environmental conditions to ensure a fast and reliable response.

09 / Drying systems

Protected area

Drying systems are key components in many industrial production processes. They are used to reduce the moisture content of materials such as wood chips, veneers, sewage sludge or animal feed. During operation, combustible materials are continuously moved and exposed to high temperatures.

These systems are typically integrated into complex arrangements of conveying, extraction and cooling air ductwork and are connected to other production stages via material infeed and discharge points. Due to the combination of heat, dust and combustible media, they represent an area with particularly high fire risk.

Risks

- Overheating, friction or mechanical failure during operation

- Introduction of embers via conveying or feed systems

- Accumulation of combustible dusts or residues inside the dryer

- Ignition of thermal oils or lubricating greases

- Rapid fire spread caused by airflow and dust concentrations

Solution

For drying systems, finely atomised water extinguishing systems (such as those from Marioff, VID Firekill or Econaqua) are primarily used to suppress fires quickly and precisely. The generated water mist effectively absorbs heat, cools the fire source and significantly reduces the amount of extinguishing water compared with conventional sprinkler systems — ideal for sensitive production environments.

In adjacent control, filter or conveyor areas, AccurateFlow provides an effective additional layer of protection: by using inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is selectively reduced and the risk of re-ignition is reliably prevented — residue-free and gentle on materials.

10 / Test benches

Protected area

Test benches are used across numerous industrial sectors — from the automotive and energy industries to materials testing. They are designed to simulate extreme operating conditions such as temperature, pressure or vibration, as well as to ensure the quality of complex components. Depending on the application, they are constructed as enclosed test cells or open test areas and incorporate electrical, mechanical and hydraulic systems with high power density.

Risks

- Overheating of test samples, drives or test equipment

- Leaks of fuels, hydraulic oils or cooling media

- Electrical faults or short circuits in measurement and control systems

- Hot surfaces or spark generation as potential ignition sources

Solution

Fire protection for test benches depends on the specific testing conditions.

In enclosed test chambers or engine test benches, AccurateFlow ensures reliable, residue-free fire suppression. Inert gas technology using nitrogen (IG-100), argon (IG-01), IG-55 or IG-541 reduces the oxygen concentration with precision and prevents consequential damage to sensitive sensors and electronics.

In open or semi-open test areas, finely atomised water mist systems provide effective cooling and fire limitation with minimal water usage.

Fire detection is carried out via a fire detection system equipped with flame, heat or aspirating smoke detectors, which respond to temperature increases or smoke particles at an early stage to ensure rapid activation.

11 / Pneumatic extraction and conveying systems

Protected area

Pneumatic extraction and conveying systems are used in industrial facilities to transport and remove materials such as wood dust, plastic granulate, paper fibres or food components. They connect processing machines, filter systems and silos through a branched ducting network in which large volumes of air move at high velocity.

Due to friction, material movement and process heat, these systems present an increased fire and explosion risk, requiring a specifically tailored protection concept.

Risks

- Introduction of sparks, hot particles or embers from machinery

- Dust explosions caused by high concentrations of combustible dust

- Frictional heat at deflection points, throttles or fans

- Ignition sources from metallic foreign objects or mechanical damage

- Fire spread through ductwork into downstream system components

Solution

In pneumatic conveying lines, automatic spark and ember detection systems are used. Infrared detectors continuously monitor the material flow and detect the thermal radiation of passing particles in real time. Upon detecting a spark, the system activates the extinguishing mechanism within milliseconds: fast-acting nozzles generate a fine water curtain that immediately cools the particles without interrupting the material flow.

In downstream areas — such as filter chambers, collection vessels or control units — AccurateFlow complements the protection concept. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), embers and re-ignition are reliably suppressed — residue-free, gentle on materials and low-maintenance.

12 / Electrical and control rooms

Protected Area

Electrical and control rooms are central control and distribution areas within industrial facilities. They contain switchgear, control units and communication components that ensure the operation of electrical and automated processes. The equipment is often installed on raised floors, beneath which extensive cabling is routed. Due to the high power density and their critical importance to the overall facility, even minor faults can lead to production downtime or system failures.

Risks

- Electrical short circuits caused by overload or insulation faults

- Overheating due to insufficient ventilation

- Ignition of cable insulation or plastic housings

- Technical defects or operating errors

- Dust and dirt accumulation inside switchgear panels

Solution

AccurateFlow protects electrical and control rooms through the targeted use of inert gases (IG-100, IG-01, IG-55, IG-541), ensuring rapid and residue-free fire suppression. The oxygen concentration is reduced to a level at which the combustion reaction ceases, without affecting the sensitive electrical infrastructure.

Activation is carried out via a fire detection system with a highly sensitive aspirating smoke detection system or point-type detectors. This ensures early activation — providing maximum operational reliability and minimal downtime.

13 / Control rooms

Protected Area

Control rooms centralise all control, monitoring and safety processes within an industrial facility. They aggregate data from various systems, monitor operating conditions and evaluate fault messages — often in 24-hour operation. The rooms are equipped with control consoles, monitors and extensive IT and communication technology. Due to the high concentration of equipment, continuous load and their critical importance for plant operation, control rooms are considered particularly sensitive areas.

Risks

- Short circuits or technical faults in control and monitoring systems

- Overheating of computers, displays or server components

- Local heat accumulation due to insufficient ventilation

- Rapid fire spread within densely packed electronic equipment

- Smoke development impairing visibility and system functionality

Solution

Control rooms can be integrated into general building protection using sprinkler or pre-action systems. The latter prevent unintended activation through dual fire verification, ensuring reliable protection for sensitive electronic equipment.

Where particularly high availability is required, AccurateFlow is used. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is controlled and reduced, enabling residue-free and material-friendly fire suppression — without interrupting operations.

Detection is carried out via a fire detection system with a highly sensitive aspirating smoke detection system, which identifies even the smallest particles and ensures a rapid, automatic response.

14 / Hochöfen

Protected Area

Blast furnaces are among the most central and simultaneously most fire-prone installations in metallurgical operations. Operating at temperatures above 1,000 °C, the process runs continuously to produce molten pig iron from ore and coke. Because immediate shutdown is almost impossible in the event of a fire, the fire protection systems must function reliably under extreme thermal conditions.

In addition to the main furnace, numerous auxiliary units — such as ladles, strand-guiding systems, hydraulic equipment and conveyor belts — are located in close proximity. Oil-carrying components, deposits and dust create additional fire risks, particularly on hot surfaces and moving parts.

Risks

- Ignition of hydraulic and lubricating oils near the molten metal

- Fire hazards affecting control systems, ladles and strand-guiding equipment

- Sparks or ember carryover caused by material movement

- Deposits and dust combined with high operating temperatures

Solution

Effective fire protection for blast furnaces requires robust, temperature-resistant systems.

Finely atomised water mist extinguishing systems (e.g. Marioff technology) provide reliable protection for areas ranging from the ladle turret to the discharge roller table. They cool metallic surfaces, reduce radiant heat and prevent the spread of flames.

Flame and heat detectors are used in addition, enabling early detection and automatic activation of the extinguishing system.

This ensures dependable protection even under extreme thermal conditions — without interrupting the ongoing production process.

15 / Break rooms and office areas

Protected Area

Break rooms and office areas are among the most frequently used spaces in administrative and operational buildings. They are places for work, communication and rest — including individual and open-plan offices, conference rooms, kitchenette areas, break zones and adjacent circulation spaces. These rooms serve not only daily work organisation but also the well-being and safety of personnel.

Due to the large number of electrical devices and the high level of daily use, they place specific demands on preventive fire protection.

Risks

- Faults in electrical devices (computers, monitors, printers, projectors)

- Overheating of lighting or heating systems

- Short circuits or smouldering fires in vending machines or small appliances

- Ignition of easily combustible materials such as paper or textiles

- Unattended devices in kitchenette or break areas

Solution

For office areas and break rooms, water-based extinguishing systems provide fast and reliable response. Water mist systems offer a particularly efficient solution, as they cool the fire source precisely while significantly reducing water consumption and potential consequential damage. In areas with higher fire loads or large room volumes, automatic sprinkler systems ensure comprehensive area protection — providing maximum personal safety and safeguarding operational continuity.

16 / Server rooms

Protected Area

Server rooms are among the most sensitive areas of modern IT infrastructure. They store, process and distribute central data across networks. These systems require a stable environment with constant temperature, controlled humidity and an uninterrupted power supply. Even short outages or fire events can have serious consequences for operational processes and data security — potentially leading to production stoppages or financial losses. A precisely coordinated fire protection concept is therefore indispensable.

Risks

- Overheating of server and network systems

- Electrical faults or short circuits

- Local heat accumulation caused by improper airflow

- Rapid fire and smoke development even from small ignition sources

- Significant consequential damage from heat, smoke or inappropriate extinguishing agents

Solution

For enclosed IT areas, AccurateFlow provides highly effective and residue-free protection. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration in the room is reduced to a level at which fires are reliably suppressed — without affecting the hardware. Extinguishing is uniform and controlled, allowing ongoing operations to continue with minimal interruption.

Activation is carried out via a fire detection system with an aspirating smoke detection system or multi-sensor detection, which identifies even minimal particle concentrations and responds at an early stage. This creates a clean, sustainable and operationally reliable fire protection concept for sensitive IT infrastructures.

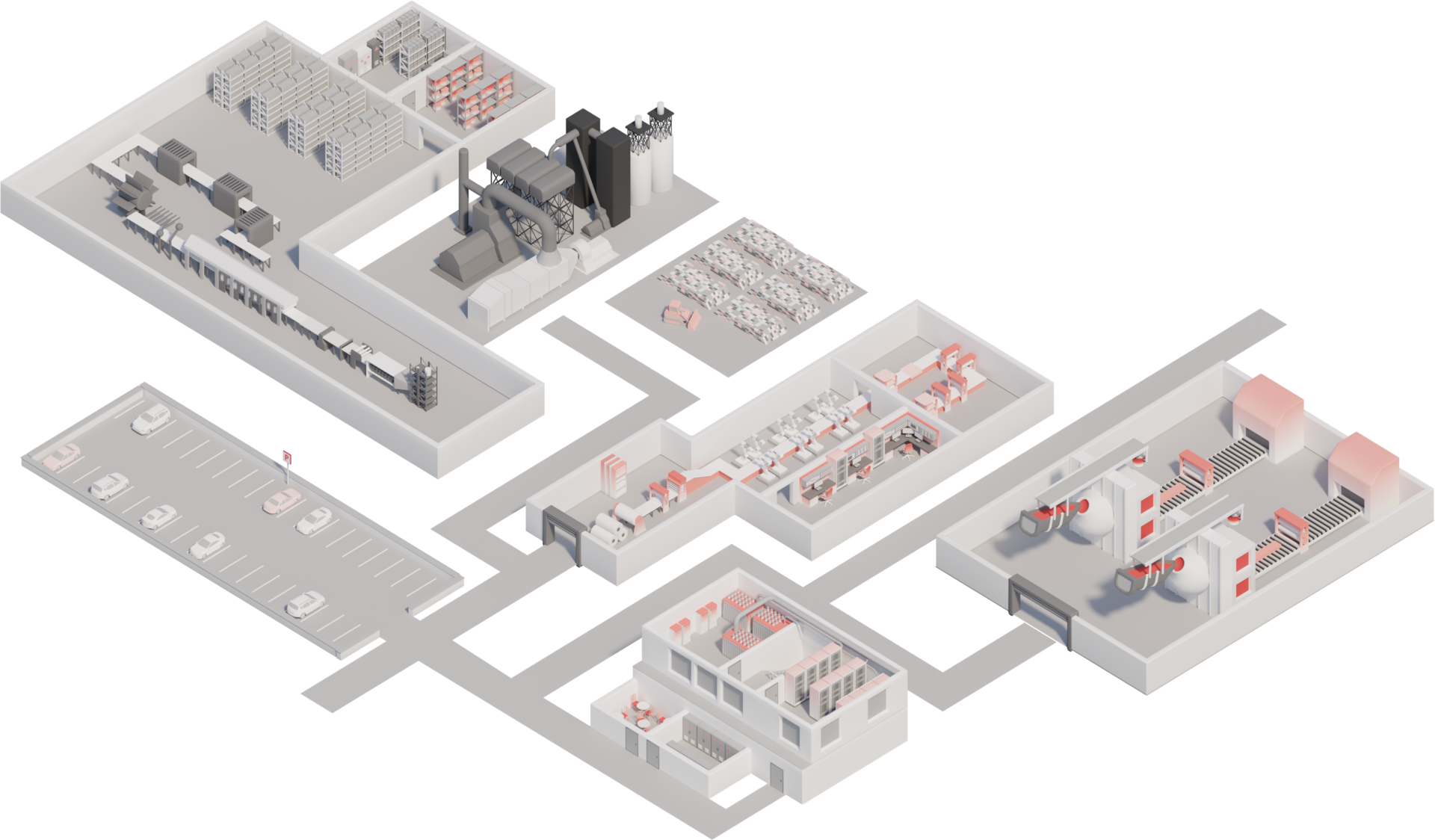

In industrial facilities, virtually the entire spectrum of extinguishing system technologies is used. Depending on the specific industry and the existing fire load — for example, due to stored materials or specialised production processes — an individual fire protection concept is developed. Different systems are often combined, such as sprinkler systems for production areas, fire detection systems for office and administrative spaces, and gas extinguishing systems for sensitive electrical and server rooms. ACCURO takes a holistic approach to every project and integrates the appropriate systems into an efficient, precisely coordinated overall concept — both nationally and internationally.

Industrial warehouses place special demands on fire protection. In most cases, automatic sprinkler systems are used, tailored to the specific storage structure and fire load.However, if the stored goods are sensitive to extinguishing water or if large amounts of water would cause significant consequential damage, water mist systems are an efficient alternative.

For exterior areas at risk of frost, dry pipe systems or systems with antifreeze solutions are used.

In special warehouses, such as those for hazardous materials, ACCURO develops customised protection concepts that precisely take into account the type and quantity of the stored substances.

In production facilities, high energy densities, continuous machine processes, and a wide range of materials come together — an environment in which even the smallest ignition sources can have serious consequences. Fire protection in industrial manufacturing must therefore be precisely adapted to the specific processes, materials, and equipment involved.

ACCURO provides holistic fire protection concepts — from risk analysis to technical planning, implementation, and commissioning. Depending on the type of production and fire load, different extinguishing systems are used, such as sprinkler systems for large production halls, water spray or water mist systems for machine and equipment cooling, foam extinguishing systems for flammable liquids, oils, or lubricants, and gas extinguishing systems (AccurateFlow) for electrical control centres, switch rooms, and monitoring systems.

The protection is complemented by fire detection systems, smoke and heat exhaust systems (RWA), and automated monitoring systems that detect fires at an early stage and contain them in a targeted manner. Through this combination of preventive detection, rapid response, and reduced extinguishing agent use, ACCURO not only protects production facilities and machinery but also ensures the continuity of critical manufacturing processes. The result is intelligent, efficient, and sustainable fire protection solutions — perfectly tailored to the requirements of modern industrial production.