Protected areas

01 / Delivery zones

Protected area

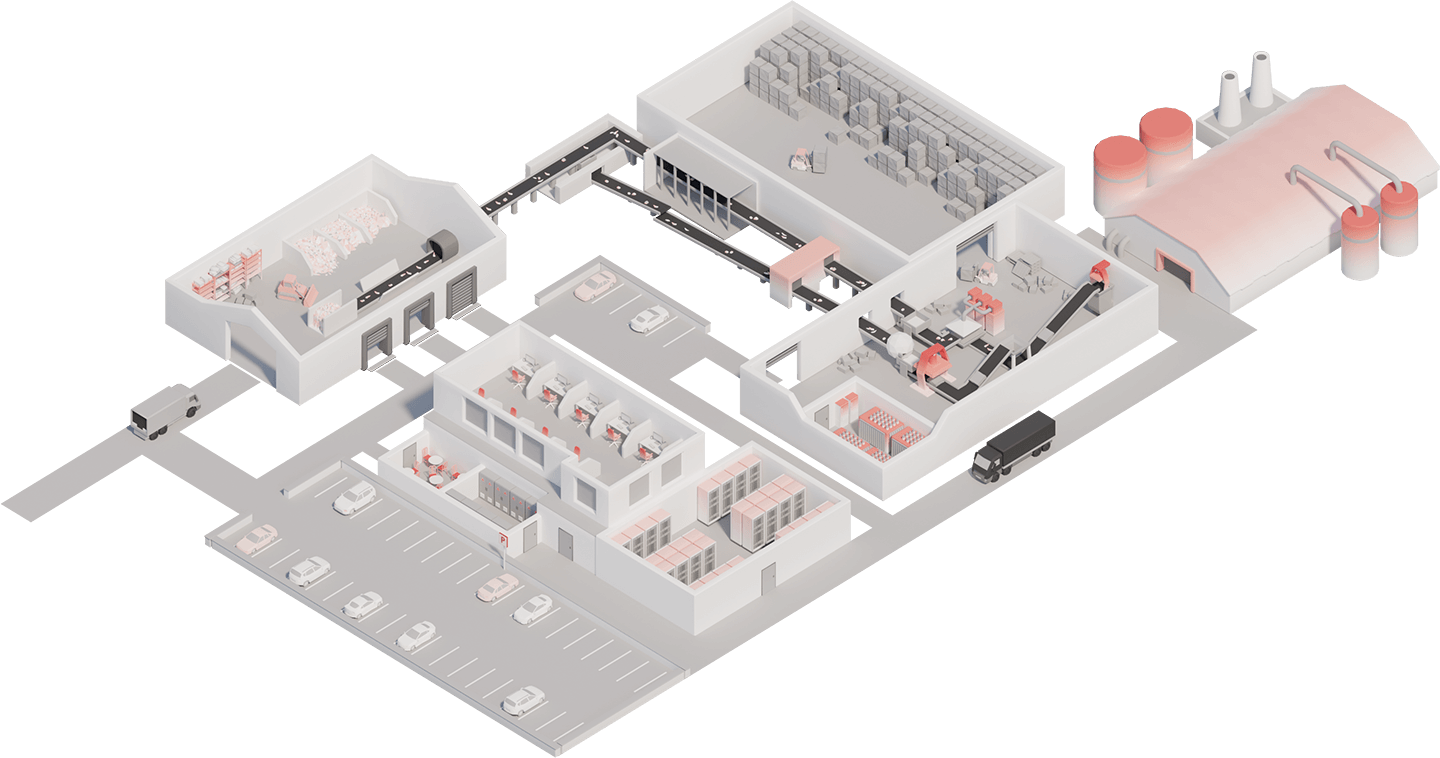

Delivery zones are used for receiving and temporarily storing raw materials, auxiliary materials and operating supplies, making them a central component of internal material flow. Depending on the facility design, deliveries take place either outdoors or within covered hall areas — often with both variants operating in parallel. High vehicle frequency, intensive forklift traffic and temporarily stored materials are characteristic features of these zones. These factors create an increased fire risk that requires a reliable and adaptable protection concept.

Risks

- Self-ignition of delivered or stored materials

- Formation of explosive atmospheres due to dust or vapours

- Arson or carelessly discarded cigarette remnants in outdoor areas

- Technical faults in trucks, loading equipment or conveyor systems

- Rapid fire spread caused by open structures and air movement

Solution

In open loading zones and outdoor areas, infrared or thermal imaging systems are used for early detection of temperature increases. If a hot spot is detected, an automatic alarm is sent to the fire detection control panel.

For targeted fire suppression, stationary or remotely operated monitors are deployed. They apply water- or foam-based extinguishing agents precisely to the fire source while simultaneously cooling adjacent structures.

In covered hall areas, sprinkler or water spray systems provide area-wide fire suppression — even in environments with large ceiling heights or increased dust levels.

Activation is automatic via a fire detection system with smoke, flame or heat detection, adapted to the respective environmental conditions to ensure a fast and reliable response.

02 / Manual sorting areas

Protcted area

Manual sorting areas are enclosed work cabins in which recyclables and material fractions are inspected and separated by hand. The materials are transported on conveyor belts, with workstations positioned on both sides along the conveying path. Lighting, ventilation and air-conditioning systems ensure ergonomic working conditions, but at the same time increase electrical and thermal loads in these areas. Due to continuous conveyor operation and the accumulation of materials, an elevated fire risk is present.

Risks

- Overheating or faults in electrical components of lighting or ventilation systems

- Overheated roller bearings in adjacent conveyor equipment

- Accumulations of dust or fibres with high flammability

- Rapid fire spread along the conveyor path

Solution

In sorting cabins, fire protection is ensured by sprinkler systems integrated into the existing building protection infrastructure. In addition, fire detection systems with optical smoke detectors or multi-sensor gas detectors are installed to precisely detect changes in temperature and smoke.

In areas with elevated dust levels, point-type heat detectors are used to prevent false alarms and ensure operational reliability.

03 / Mechanical processing of recyclables

Protected area

In mechanical processing, recyclables are shredded, sorted, separated and prepared for reuse. Depending on the material type, various technologies such as mechanical, magnetic or pneumatic separation are employed. Typical system components include shredders, crushers, trommel screens, air classifiers, magnetic separators and vibratory conveyors.

During these processes, significant heat is generated due to friction, impact energy and material contact. In combination with dust deposits and combustible materials, this results in a particularly high fire risk — especially in recycling facilities with continuous system operation.

Risks

- Overheating of motors, roller bearings or compressors

- Sparking during cutting, maintenance or welding work

- Self-ignition of conveyed materials or dust deposits

- High fire load due to concentrated materials in confined spaces

- Rapid fire spread along conveyor routes

Solution

For processing plants, a fast-acting and area-wide extinguishing system is essential. Water spray systems with foam concentrate proportioning from FireDos provide a particularly effective solution: they ensure uniform fire suppression and prevent spread to adjacent system components.

Fire detection is carried out via a fire detection system equipped with flame and multi-sensor gas detectors, which evaluate temperature, smoke and gases in combination to enable early and reliable activation.

When automatic extinguishing monitors are used, detection and precise targeting of the monitor are handled by the DIAS detection system.

04 / Parking areas

Protected area

Parking areas and underground car parks are integral components of modern building structures. They provide parking spaces for employees, customers and visitors, and are often designed as multi-storey or underground facilities. Due to the high vehicle density, limited air circulation and intensive use, they place special demands on ventilation, smoke extraction and fire protection. In addition to ensuring personal safety, the primary focus is on containing vehicle fires and preventing the spread of smoke.

Risks

- Technical faults in vehicles (e.g. short circuits, battery or fuel fires)

- Careless smoking or open flames

- Arson or intentional ignition sources

- Rapid fire and smoke development due to confined structural layout

- Heat accumulation and insufficient smoke extraction in lower levels

Solution

In parking structures and underground car parks, water-based extinguishing systems are primarily used to quickly suppress fires and prevent them from spreading to adjacent vehicles. Water mist systems from Marioff or VID Firekill nozzles provide a particularly efficient and resource-conserving solution, as they achieve strong cooling performance with minimal water consumption and reduce consequential damage.

For large ceiling heights or expansive parking decks, automatic sprinkler systems are used. They are supplied via the existing firefighting water network and ensure uniform area coverage.

A fire detection system with smoke or heat sensing ensures early alarm activation — providing maximum protection for people and property in highly frequented parking areas.

05 / Break rooms and office areas

Protected Area

Break rooms and office areas are among the most frequently used spaces in administrative and operational buildings. They are places for work, communication and rest — including individual and open-plan offices, conference rooms, kitchenette areas, break zones and adjacent circulation spaces. These rooms serve not only daily work organisation but also the well-being and safety of personnel.

Due to the large number of electrical devices and the high level of daily use, they place specific demands on preventive fire protection.

Risks

- Faults in electrical devices (computers, monitors, printers, projectors)

- Overheating of lighting or heating systems

- Short circuits or smouldering fires in vending machines or small appliances

- Ignition of easily combustible materials such as paper or textiles

- Unattended devices in kitchenette or break areas

Solution

For office areas and break rooms, water-based extinguishing systems provide fast and reliable response. Water mist systems offer a particularly efficient solution, as they cool the fire source precisely while significantly reducing water consumption and potential consequential damage. In areas with higher fire loads or large room volumes, automatic sprinkler systems ensure comprehensive area protection — providing maximum personal safety and safeguarding operational continuity.

06 / Mechanical conveyor systems

Protected area

Mechanical conveyor systems are an essential component of many industrial production processes. They transport raw materials, auxiliary materials and operating supplies between individual processing stations via belt, roller or chain conveyors. These systems may be designed as open or enclosed units and often extend across multiple levels and building sections. Due to continuous movement, friction and their proximity to other production equipment, they present an increased fire risk that requires a fast and targeted extinguishing response.

Risks

- Overheating of roller bearings, drives or shafts

- Sparking caused by maintenance or welding work

- Self-ignition of conveyed materials due to friction or material build-up

- Fire spread along conveyor routes

- Difficult fire suppression due to enclosed constructions or continuous material flow

Solution

For conveyor systems, water spray extinguishing systems are used, providing an immediate and area-wide response along the entire conveyor route. They effectively suppress open flames and prevent fire spread to adjacent system components.

In sensitive production environments or where low water consumption is required, finely atomised water mist systems are deployed. They rapidly reduce temperatures, bind smoke particles and minimise consequential damage.

Fire detection is carried out via a fire detection system with flame or multi-sensor gas detectors, which precisely register changes in temperature and smoke.

07 / Storage rooms

Protected area

Storage rooms are used for the orderly storage of materials, products and operating supplies. Depending on their purpose, they may contain office and consumable items, cleaning and hygiene products, tools, spare parts or merchandise. In some cases, refrigerated or deep-freeze units are integrated, which place additional demands on ventilation, temperature control and fire protection.

The wide variety of stored goods and packaging materials results in differing fire loads and requires a coordinated protection concept.

Risks

- Short circuits in electrical wiring or distribution cabinets

- Carelessly discarded cigarettes or other ignition sources

- High fire load due to densely stored materials and packaging

- Rapid fire spread in the absence of fire compartmentation

- Overheating of equipment or lighting systems

Solution

In storage and logistics areas, sprinkler or water spray systems are primarily used. They ensure area-wide cooling and rapid fire suppression, with sprinklers also being integrated directly into rack systems depending on the storage type. Cold storage rooms are safely incorporated into the extinguishing concept using dry sprinklers to prevent the pipe network from freezing.

In enclosed storage rooms or areas with particularly high-value goods, AccurateFlow provides an effective additional layer of protection. By using inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is reduced and combustion is reliably suppressed — residue-free, gentle on materials and low-maintenance.

08 / Server rooms

Protected Area

Server rooms are among the most sensitive areas of modern IT infrastructure. They store, process and distribute central data across networks. These systems require a stable environment with constant temperature, controlled humidity and an uninterrupted power supply. Even short outages or fire events can have serious consequences for operational processes and data security — potentially leading to production stoppages or financial losses. A precisely coordinated fire protection concept is therefore indispensable.

Risks

- Overheating of server and network systems

- Electrical faults or short circuits

- Local heat accumulation caused by improper airflow

- Rapid fire and smoke development even from small ignition sources

- Significant consequential damage from heat, smoke or inappropriate extinguishing agents

Solution

For enclosed IT areas, AccurateFlow provides highly effective and residue-free protection. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration in the room is reduced to a level at which fires are reliably suppressed — without affecting the hardware. Extinguishing is uniform and controlled, allowing ongoing operations to continue with minimal interruption.

Activation is carried out via a fire detection system with an aspirating smoke detection system or multi-sensor detection, which identifies even minimal particle concentrations and responds at an early stage. This creates a clean, sustainable and operationally reliable fire protection concept for sensitive IT infrastructures.

09 / Wall openings

Schutzbereich

Wall openings (e.g. for conveyor belts, piping or material transfer points) interrupt structural fire compartmentation and create potential pathways for fire, smoke and heat. To maintain the required separation, water-based barriers — ‘water curtains’ or water walls — are installed at these openings. These systems generate a continuous, uniform sheet of water in front of the opening, ensuring the necessary separation between adjacent fire zones without significantly impairing the functionality of the passage.

Risks

- Direct fire spread through the opening

- Smoke ingress and radiant heat transfer into adjacent sections

- Transfer of sparks or embers via conveying equipment

- Insufficient water coverage due to pressure or nozzle faults

- Freezing, clogging or corrosion of nozzles and piping

- Operating errors or inadequate system maintenance

Solution

The water curtain operates with a targeted nozzle arrangement and hydraulic supply system (monitor network) that creates a continuous, overlapping sheet of water in front of the opening. Typical features include redundant pumps, pressure-maintaining vessels, frost and corrosion protection, pressure-regulated valves and a controlled drainage system. Activation is automatic via the fire detection system (flame, heat or aspirating smoke detection) and can be supplemented by local manual controls.

Where there is an increased risk of flammable liquid fires, the water curtain can be combined with foam proportioning; otherwise, a pure water mist or water film ensures rapid cooling, reduction of radiant heat and an effective barrier function. Regular functional testing, nozzle inspection and documented maintenance cycles are essential to ensure long-term effectiveness.

10 / Electrical and control rooms

Protected Area

Electrical and control rooms are central control and distribution areas within industrial facilities. They contain switchgear, control units and communication components that ensure the operation of electrical and automated processes. The equipment is often installed on raised floors, beneath which extensive cabling is routed. Due to the high power density and their critical importance to the overall facility, even minor faults can lead to production downtime or system failures.

Risks

- Electrical short circuits caused by overload or insulation faults

- Overheating due to insufficient ventilation

- Ignition of cable insulation or plastic housings

- Technical defects or operating errors

- Dust and dirt accumulation inside switchgear panels

Brandschutz

AccurateFlow protects electrical and control rooms through the targeted use of inert gases (IG-100, IG-01, IG-55, IG-541), ensuring rapid and residue-free fire suppression. The oxygen concentration is reduced to a level at which the combustion reaction ceases, without affecting the sensitive electrical infrastructure.

Activation is carried out via a fire detection system with a highly sensitive aspirating smoke detection system or point-type detectors. This ensures early activation — providing maximum operational reliability and minimal downtime.

11 / Pressing and compaction systems

Protected area

Pressing and compaction systems are used to reduce the volume of recyclables and process them into bales or briquettes. Depending on the material and method, the systems operate using hydraulic pressure, heat or binding agents. The combination of high forces, elevated temperatures and oil-bearing components creates an increased fire risk — particularly in enclosed or semi-enclosed system areas with continuous operation.

Risks

- Deposits of hydraulic or thermal oils on hot surfaces

- Leaks in hydraulic lines or connections

- Self-ignition caused by frictional heat or overheating of the press mechanism

- Sparking during maintenance, cleaning or repair work

Solution

For hydraulically operated presses and compaction systems, water spray extinguishing systems with foam proportioning from FireDos provide reliable protection. They are highly effective against oil-based fire loads, cool rapidly and prevent fire spread.

Alternatively, finely atomised water mist systems can be used. They significantly reduce the amount of extinguishing water required, lower temperatures quickly and protect sensitive electronics from secondary damage.

Fire detection is carried out using flame or multi-sensor gas detectors, which are connected to the central fire detection system and enable fast, automatic activation.

In enclosed system areas, protection can be supplemented with AccurateFlow. The system uses inert gases (IG-100, IG-01, IG-55, IG-541) to suppress fires without leaving residues — ideal for areas where water or foam cannot be applied.

12 / Waste incineration plants

Protected Area

Waste incineration plants are used for the thermal treatment of municipal, commercial and industrial waste to generate energy. The combustion process takes place in several stages — from waste delivery and fuel feeding to the grate or rotary kiln, followed by flue gas cleaning and energy recovery.

Due to high temperatures, combustible residues and complex conveying and airflow systems, these facilities present demanding fire risks. In addition to the furnace itself, fuel feed systems, ash conveyors, filter units and boiler sections are among the most critical zones.

Risks

- Introduction of embers from the waste bunker into the fuel feed system

- Backfire or deflagration in furnace and feed areas

- Accumulation of combustible materials in ducts, filters and heat exchangers

- Overheating of mechanical or electrical components

- Dust explosions in flue gas cleaning or during ash handling

Solution

Effective fire protection for waste incineration plants requires a multi-stage protection concept.

In fuel feed systems, conveying paths and filter areas, water spray or finely atomised water mist extinguishing systems are used to suppress fires quickly and prevent re-ignition.

Fire detection is carried out using flame and heat detectors, combined with IR/UV sensor technology for early identification of ignition sources and embers.

This ensures safe and uninterrupted operation even under extreme thermal and mechanical conditions.

In waste incineration and recycling plants, the processing and combustion of waste materials are an integral part of daily operations. However, the situation becomes critical when an uncontrolled fire breaks out. Unfortunately, such incidents are not uncommon and can quickly escalate into a serious threat.

The high fire load of stored waste materials provides ideal conditions for rapid and devastating fires. These incidents not only endanger people on site, but can also cause significant environmental damage, operational downtime, and severe economic consequences. In many cases, the company’s reputation is also affected.

To effectively counter these risks, a holistic and tailor-made fire protection concept is essential. A particularly decisive factor is the early detection and immediate suppression of incipient fires.

The use of automatic fire extinguishing systems ensures that fires are controlled at an early stage – before they can spread and pose a serious threat to the operation, the surrounding area, and the environment.

Fire protection in power plants covers the full range of modern extinguishing and fire detection technologies. Depending on the type of plant, water spray, water mist, foam, or gas extinguishing systems, as well as highly sensitive fire detection and monitoring systems, are used.

ACCURO has equipped numerous power plants worldwide — working closely with international partners and operators. Project planning is always tailored to the customer and the specific country to meet the highest safety standards.

In addition to technical expertise, ACCURO is distinguished by its extensive international experience: intercultural competence and an understanding of regional requirements play a decisive role in the success of complex energy projects.

In tank farms and refineries where flammable liquids such as gasoline, diesel, or kerosene are stored, the use of firefighting foam is the only effective method for safely combating fires. The extinguishing concept is always tailored to the specific tank design and the stored medium.

For floating-roof tanks, the focus is on the sensitive contact points between the liquid and oxygen. A rim seal extinguishing system is used here, which, in combination with a linear heat detection cable, detects and extinguishes fires at an early stage.

Fixed-roof tanks, on the other hand, are protected by introducing firefighting foam into the tank. The foam floats on the burning liquid, separates it from the oxygen supply, and thereby smothers the fire. In addition, the outer shell of the tanks is continuously sprayed with water via cooling ring lines with nozzles. This permanent cooling prevents overheating and reduces the risk of a fire spreading from one tank to adjacent facilities.

At sea, fire protection presents a particular challenge: confined spaces, high temperatures, and complex machinery require systems that operate efficiently, safely, and reliably at the same time. High-pressure water mist systems offer the most effective solution in this environment. They extinguish fires quickly and precisely while barely affecting ongoing operations.

Their key advantages include low water consumption, environmental friendliness due to the absence of harmful substances, marine approval, and safety for personnel. In addition, they cause only minimal water damage, are effective even in hard-to-reach or confined areas, and therefore ensure maximum operational safety.

Water mist systems thus combine efficient fire suppression with the highest level of safety — making them ideal for use on ships, oil rigs, and offshore platforms.

In transformers and substations, there is a fire hazard due to the overheating of insulating oils. If their ignition temperature is exceeded, an explosive fire can develop.

For fire detection, linear heat detection cables are used, which immediately register temperature changes. Water spray extinguishing systems are employed as the extinguishing technology.

These systems ensure even water distribution across the entire protection area, rapidly cool overheated components, and prevent re-ignition.

Thanks to fast and targeted extinguishing, systems can be put back into operation after a short inspection — without long downtimes.