Protected areas

01 / Break rooms and office areas

Protected Area

Break rooms and office areas are among the most frequently used spaces in administrative and operational buildings. They are places for work, communication and rest — including individual and open-plan offices, conference rooms, kitchenette areas, break zones and adjacent circulation spaces. These rooms serve not only daily work organisation but also the well-being and safety of personnel.

Due to the large number of electrical devices and the high level of daily use, they place specific demands on preventive fire protection.

Risks

- Faults in electrical devices (computers, monitors, printers, projectors)

- Overheating of lighting or heating systems

- Short circuits or smouldering fires in vending machines or small appliances

- Ignition of easily combustible materials such as paper or textiles

- Unattended devices in kitchenette or break areas

Solution

For office areas and break rooms, water-based extinguishing systems provide fast and reliable response. Water mist systems offer a particularly efficient solution, as they cool the fire source precisely while significantly reducing water consumption and potential consequential damage. In areas with higher fire loads or large room volumes, automatic sprinkler systems ensure comprehensive area protection — providing maximum personal safety and safeguarding operational continuity.

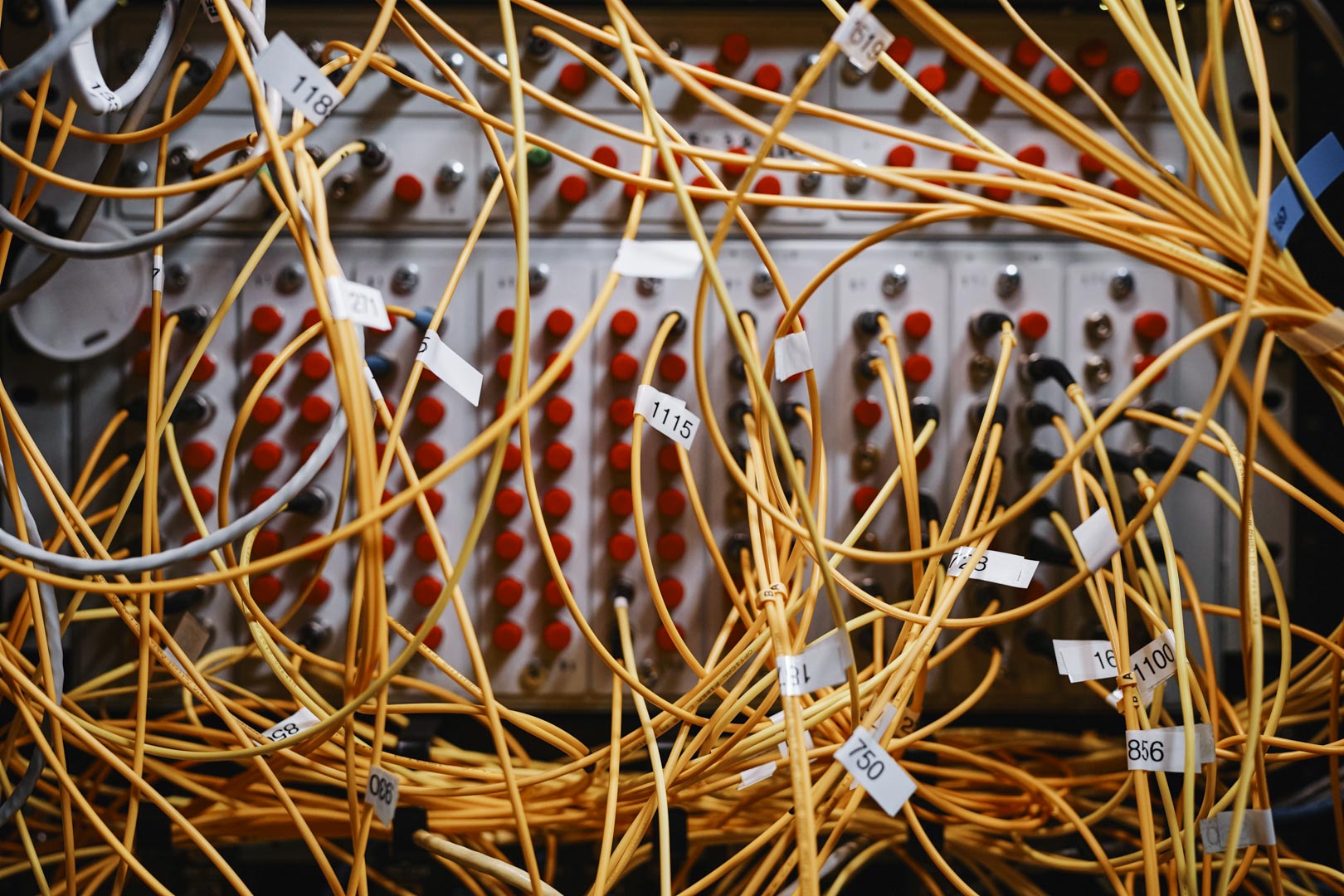

02 / Electrical and control rooms

Protected Area

Electrical and control rooms are central control and distribution areas within industrial facilities. They contain switchgear, control units and communication components that ensure the operation of electrical and automated processes. The equipment is often installed on raised floors, beneath which extensive cabling is routed. Due to the high power density and their critical importance to the overall facility, even minor faults can lead to production downtime or system failures.

Risks

- Electrical short circuits caused by overload or insulation faults

- Overheating due to insufficient ventilation

- Ignition of cable insulation or plastic housings

- Technical defects or operating errors

- Dust and dirt accumulation inside switchgear panels

Solution

AccurateFlow protects electrical and control rooms through the targeted use of inert gases (IG-100, IG-01, IG-55, IG-541), ensuring rapid and residue-free fire suppression. The oxygen concentration is reduced to a level at which the combustion reaction ceases, without affecting the sensitive electrical infrastructure.

Activation is carried out via a fire detection system with a highly sensitive aspirating smoke detection system or point-type detectors. This ensures early activation — providing maximum operational reliability and minimal downtime.

03 / Server rooms

Protected Area

Server rooms are among the most sensitive areas of modern IT infrastructure. They store, process and distribute central data across networks. These systems require a stable environment with constant temperature, controlled humidity and an uninterrupted power supply. Even short outages or fire events can have serious consequences for operational processes and data security — potentially leading to production stoppages or financial losses. A precisely coordinated fire protection concept is therefore indispensable.

Risks

- Overheating of server and network systems

- Electrical faults or short circuits

- Local heat accumulation caused by improper airflow

- Rapid fire and smoke development even from small ignition sources

- Significant consequential damage from heat, smoke or inappropriate extinguishing agents

Solution

For enclosed IT areas, AccurateFlow provides highly effective and residue-free protection. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration in the room is reduced to a level at which fires are reliably suppressed — without affecting the hardware. Extinguishing is uniform and controlled, allowing ongoing operations to continue with minimal interruption.

Activation is carried out via a fire detection system with an aspirating smoke detection system or multi-sensor detection, which identifies even minimal particle concentrations and responds at an early stage. This creates a clean, sustainable and operationally reliable fire protection concept for sensitive IT infrastructures.

04 / Transformers

Protected area

Transformers form the link between power generation and grid distribution. They convert electrical energy to the required voltage level and thus ensure a stable power supply. Typically, they consist of an oil-filled housing, cooling systems, oil expansion tanks and high-voltage bushings. Due to their high electrical output and the large volume of insulating oil, transformers are considered highly safety-critical components.

Risks

- Short circuits or electrical arcing inside the transformer

- Overheating of windings or contacts

- Leaks and release of insulating oil

- Oil fires resulting from electrical malfunctions or explosions

- Fire spread to adjacent system areas

Solution

For oil-cooled transformers, water mist or water spray extinguishing systems are primarily used. They cool the affected areas rapidly, reduce fire intensity and prevent further spread. The fine mist enables highly efficient heat absorption while using significantly less water than conventional sprinkler systems.

Activation is carried out via a fire detection system with flame, heat or smoke detection, ensuring an early response.

In enclosed transformer rooms, AccurateFlow can be used additionally. By selectively introducing inert gases (IG-100, IG-01, IG-55, IG-541), the oxygen concentration is reduced to a level at which fires are reliably suppressed — residue-free, gentle on materials and operationally secure.

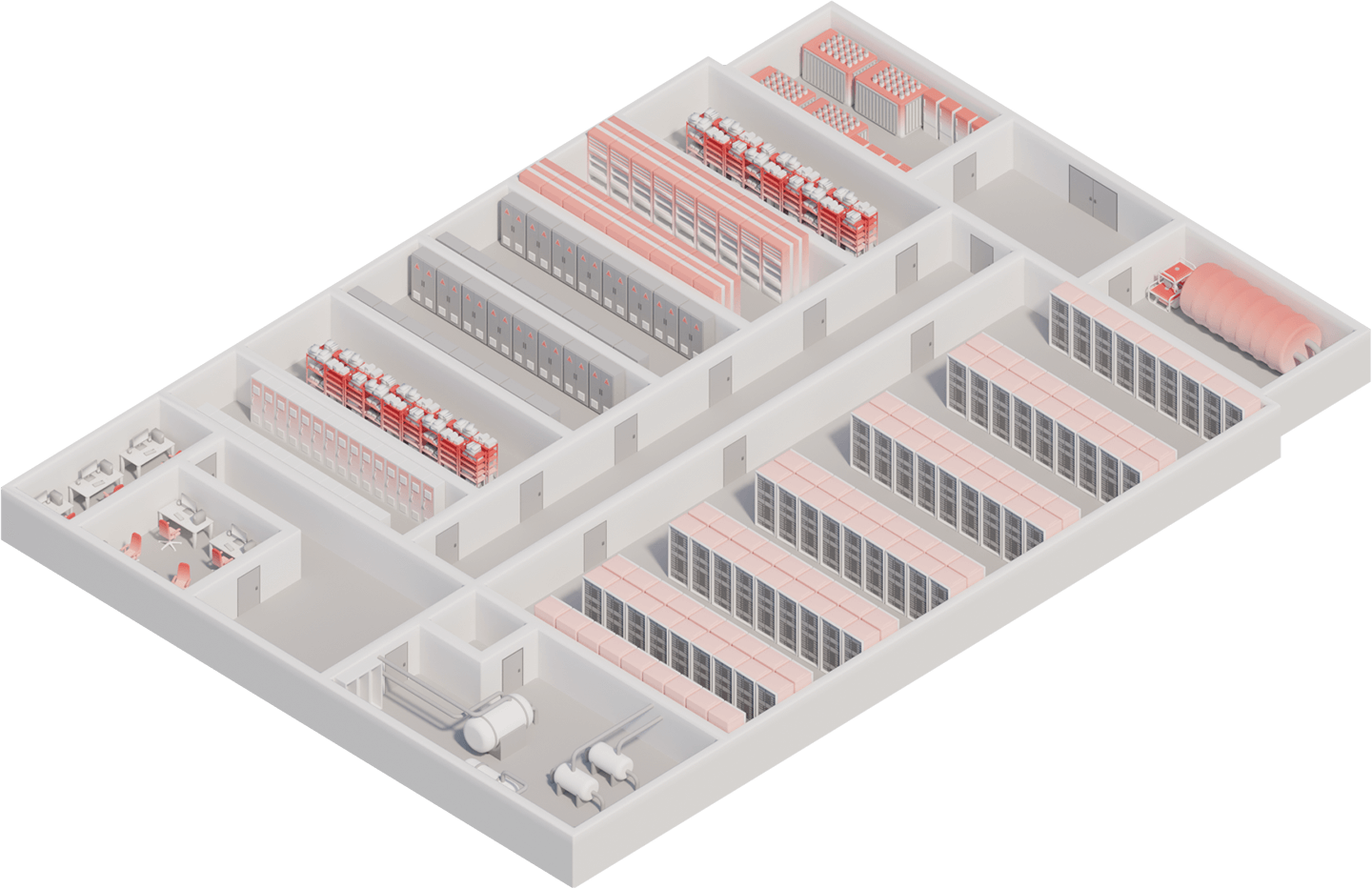

05 / Data center server and computing rooms

Protected area

Server and computing rooms form the core of modern data centers. The IT systems are installed on raised floors, beneath which cable trays, airflow systems and cooling infrastructure are routed. Precision cooling units maintain constant temperature and humidity levels in dedicated zones. These systems ensure stable and failure-resistant operation of critical data and communication processes.

Risks

- High power density and continuous thermal load

- Overheating or local heat accumulation (“hot spots”)

- Electrical faults or short circuits

- Malfunctions of UPS or battery modules

- Leaks in water-based cooling systems

- Static discharges due to inadequate grounding

- Operating errors or maintenance faults

- Dust or particle contamination in airflow systems

- Insufficient monitoring of temperature, humidity and pressure

Solution

For gas-tight IT areas, AccurateFlow provides reliable and residue-free fire protection. By using inert gases — IG-100 (nitrogen), IG-01 (argon), IG-55 (argon–nitrogen mixture) and IG-541 (Inergen®) — the oxygen concentration is carefully reduced to safely suppress fires. The system extinguishes uniformly and consistently throughout the entire room volume without affecting sensitive hardware.

Activation is carried out via a fire detection system with an aspirating smoke detection system or multi-sensor detection, ensuring early fire detection and high operational reliability.

06 / Emergency power supply

Protected Area

Emergency power supply systems ensure the availability of electrical energy in the event of a power outage and thus safeguard the operation of critical infrastructure. They automatically switch to independent power generation as soon as the public grid fails, preventing production interruptions, data loss or equipment damage.

The generator units are typically installed in separate, well-ventilated rooms to ensure safe operation, efficient cooling and easy maintenance.

Risks

- Self-ignition of diesel fuel on overheated surfaces

- Leaks in fuel or lubrication oil lines

- Fire development in switchboards or control units

- Overheating due to insufficient room ventilation

- Soot, oil and dust deposits increasing the fire load

Solution

For rooms housing emergency power supply systems, water mist extinguishing systems are particularly suitable, as they suppress fires quickly and effectively without damaging sensitive components. The fine mist cools the fire source immediately and locally reduces the oxygen concentration — with minimal water consumption and low risk of consequential damage.

In enclosed or safety-critical facility areas, AccurateFlow can be used as an alternative. By precisely introducing inert gases (IG-100, IG-01, IG-55, IG-541), the fire is reliably suppressed — residue-free, gentle on materials and with maximum operational reliability. Activation is carried out via a fire detection system with flame or heat detection, ensuring a rapid response.

In data centres and IT infrastructures, a fire must be detected and extinguished in its incipient stage.

For extinguishing, ACCURO consistently relies on its in-house inert gas extinguishing system, AccurateFlow.

This system operates with natural, non-toxic gases such as Argon (IG-01), Nitrogen (IG-100), IG-55, or IG-541. They extinguish by reducing the oxygen concentration, are chemically neutral, leave no residue, are environmentally friendly — and fully comply with current European PFAS regulations.

Chemical extinguishing agents such as FM-200 or Novec™ 1230 are no longer used in new installations in Europe due to PFAS concerns. Existing systems remain permitted but are increasingly being replaced by sustainable inert gas solutions such as AccurateFlow.

With AccurateFlow, ACCURO offers future-proof, efficient, and completely residue-free fire protection — ideal for IT environments, data centres, and control rooms.

Electrical switchgear is the heart of many industrial processes — it controls, regulates, and distributes energy. Accordingly, the requirements for its fire protection are extremely high. Short circuits, overvoltages, or faulty electrical connections can trigger fires within fractions of a second, causing not only material damage but potentially shutting down entire production chains.

For this sensitive area, ACCURO primarily relies on its own inert gas extinguishing system, AccurateFlow. This system uses natural, non-corrosive, and residue-free gases such as Argon (IG-01), Nitrogen (IG-100), IG-55, or IG-541. Thanks to precise pressure regulation and uniform gas distribution, AccurateFlow ensures safe, effective, and material-friendly fire suppression without damaging electrical components.